Biomass Oil

Although several commercial attempts have been made to use RF heating in other applications, there is limited use in low bulk density applications, except for food drying (e.g., grains). Literature indicates a “run away” reaction can occur at a late stage in the drying, at high energy/rate of heating applications. This effect is believed to be the onset of torrefaction or pyrolysis and is relatively unexplored, as previous studies have focused on preserving the material properties. Because drying should be rapid, “just-in-time” inventory management may be possible. This could result in considerable storage-cost savings.

Radiofrequency energy has been successfully applied by JRT to locally obtained wood chips to achieve rapid dewatering of the chips in small bulk mass and achieve temperatures in the range of 200 -250 degrees C for torrefaction for energy density enhancement estimates.

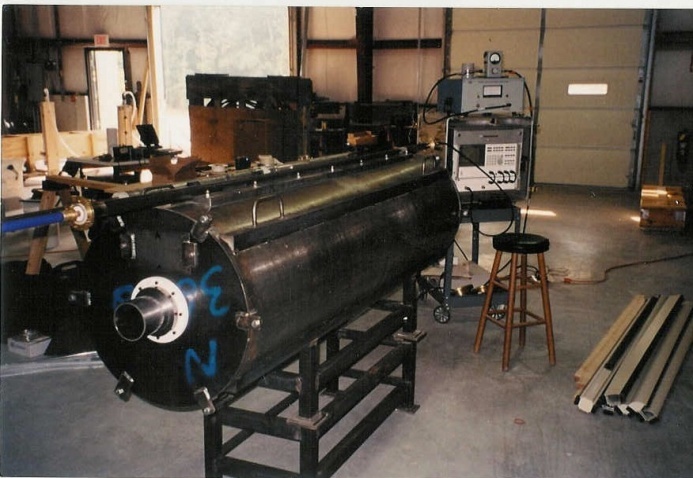

Application of RF energy to a special reactor design was preceded by a literature search on all possible RF applications performed by others and dielectric measurements of samples of wood chips obtained from Carbo as well as locally grown chips. The dielectric measurement results helped to better understand the extent possible of the RF absorption of energy by chips as well as aiding in the electromagnetic design of the experimental reactor for heating wood chips by RF energy absorption. Several different reactor designs were explored from the standpoint of efficiency of operation at the ISM (Industrial, Scientific, and Medical) frequency of 13.56MHz. The optimum design selected after several trial heating runs was compatible with an AD TEC RF generator model AQX 2000EU rated for 2000 watts of continuous RF output power into a 50 ohm load. Diagnostics and temperature measurements were performed with both the HP 8573 Network Analyzer, hand held impedance meter, and fiber optic sensor equipment

A dielectric sample holder or TEM cell is shown below used for dielectric measurements of wood samples.

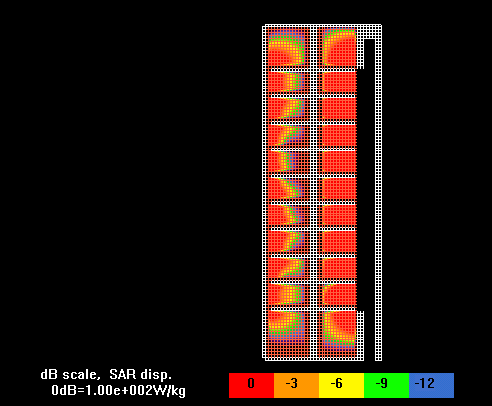

Key features of an experimental biomass reactor module reactor pictured with internal RF heating pattern are:

- Rapid and continuous RF heating throughout entire reactor volume. Auger may be used for material transport through reactor while applying RF power.

- May employ conventional vapor extraction techniques to efficiently remove liquids and vapor.

- High processing rates and possible heat recycle for higher energy efficiency.